شركة خنان ليو للطاقة الجديدة المحدودة

ما هو شكل الخلية الأفضل لسيارة فورمولا الكهربائية؟

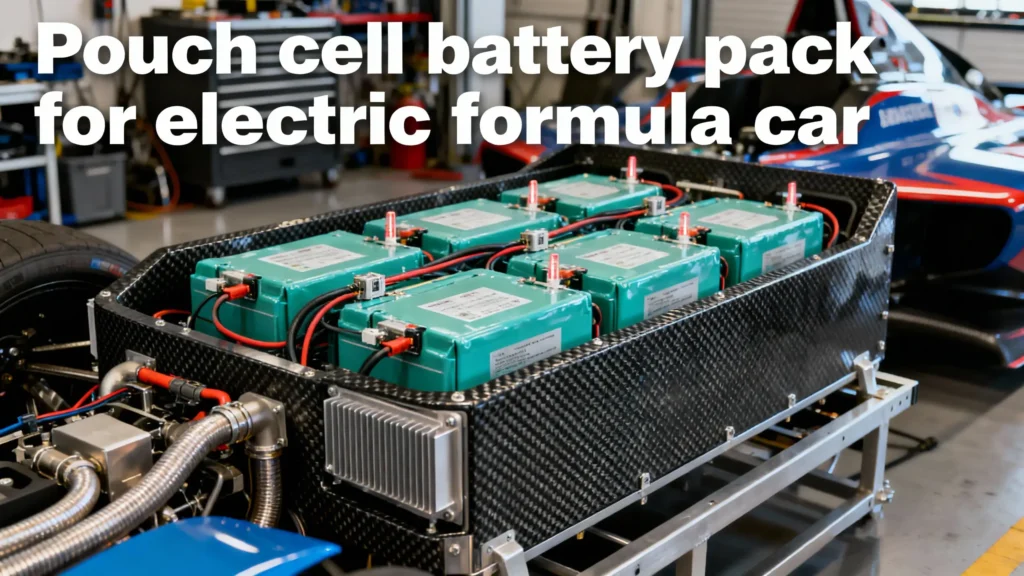

في عالم سباقات الفورمولا الكهربائية السريع، يُدفع كل مكون إلى أقصى طاقته. تتطلب حزمة البطارية، قلب السيارة ومصدر وزنها الرئيسي، الكمال. يواجه المهندسون قرارًا تصميميًا حاسمًا: ما هو شكل خلية أيون الليثيوم الأفضل لسيارة الفورمولا الكهربائية؟

يؤثر الاختيار بين الخلايا الأسطوانية والمنشورية والجيبية بشكل مباشر على الطاقة والوزن والسلامة والتصميم. بصفتنا روادًا في حلول البطاريات عالية الأداء، نُحلل الخيار الأمثل للحلبات.

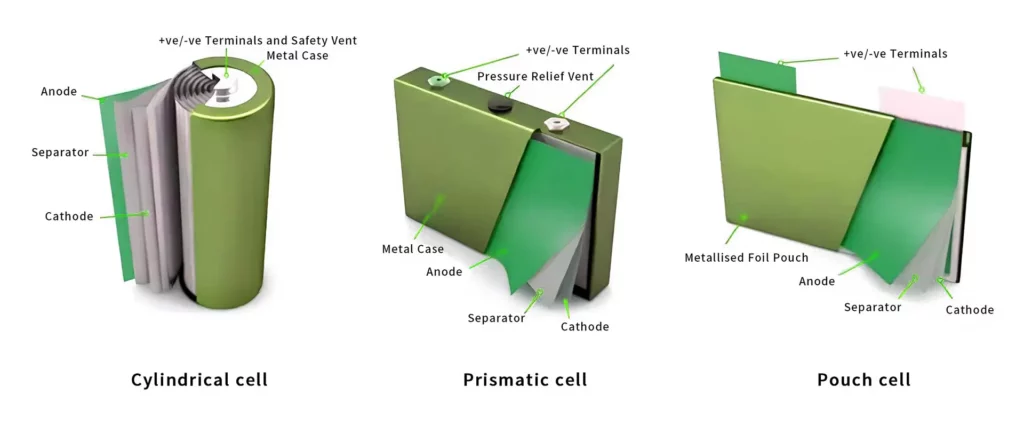

المتنافسون الثلاثة: مقارنة بين التقنيات الرئيسية

تسيطر ثلاثة أنواع من هياكل الخلايا، ولكل منها مقايضات مميزة فيما يتعلق بتطبيقات السباق.

1. الخلايا الأسطوانية (على سبيل المثال، 21700، 4680)

تتميز هذه الخلايا المألوفة ذات الغلاف الفولاذي بميكانيكا قوية وتصنيع مثبت.

تسلا‘يستخدم طراز 3 من BMW هذا النوع من البطاريات، مما يتطلب نظام إدارة بطارية قوي (BMS) لتحقيق أقصى قدر من الأداء.

- نقاط القوة: استقرار ميكانيكي فائق؛ إنتاج آلي فعال من حيث التكلفة مع اتساق عالي؛ فجوات طبيعية بين الخلايا تساعد على التبريد.

- نقاط الضعف: كثافة أقل للحزمة بسبب المساحات الفارغة؛ وزن أثقل من الأغطية والدعامات؛ عامل شكل غير مرن.

2. الخلايا المنشورية

تعد هذه الخلايا الصلبة المستطيلة ذات الغلاف المصنوع من الألومنيوم شائعة في السيارات الكهربائية الاستهلاكية.

- نقاط القوة: استخدام أفضل للمساحة مقارنة بالخلايا الأسطوانية في التصميمات المعيارية؛ سهولة التكديس والتجميع.

- نقاط الضعف: أثقل من البدائل الجيبية؛ التورم المحتمل يتطلب تصميم وحدة بعناية؛ تحديات الواجهة الحرارية.

3. خلايا الجيب

الخلايا تستخدم عبوات خفيفة الوزن ومرنة من الألومنيوم بدلاً من الأغطية الصلبة.

- نقاط القوة: أعلى كثافة للطاقة والقوة من حيث الوزن والحجم؛ تصميم خفيف الوزن؛ شكل مرن للتغليف الأمثل؛ تبديد حراري ممتاز من الأسطح الكبيرة.

- نقاط الضعف: يتطلب هيكل وحدة خارجي للدعم؛ ويحتاج إلى إدارة دقيقة للضغط للتحكم في التورم؛ ويعتبر الختم أمرًا بالغ الأهمية للموثوقية.

لماذا تفوز خلايا الجيب في سباقات الفورمولا الكهربائية؟

لتلبية المتطلبات القصوى لسيارة الفورمولا،, الخلايا الكيسية هي الفائز الواضح بين فرق السباق الرائدة. إليكم السبب:

1. نسبة قوة إلى وزن لا تقبل المنافسة: يعتمد نجاح السباقات على هذا المقياس. تُغني خلايا الجيب عن استخدام أغلفة معدنية ثقيلة، مما يجعلها الخيار الأخف وزنًا من حيث وحدة الطاقة (واط/كجم) والقوة (واط/كجم). يُحسّن تقليل الوزن بشكل مباشر التسارع والسرعة القصوى والانعطاف.

2. تغليف فائق الجودة ومركز ثقل منخفض: شكلها المسطح والمرن يُمكّن المهندسين من إنشاء حقائب كثيفة ومنخفضة الارتفاع. يمكن للفرق وضع هذه الحقائب على طول أرضية الهيكل لزيادة سعتها مع خفض مركز الثقل بشكل كبير. هذا يُعزز الثبات والتماسك عند المنعطفات.

3. ذروة أداء التفريغ والتجديد: تتميز خلايا الجيب عادةً بمقاومة داخلية أقل. وهذا يسمح بتأثير مذهل ذروة إنتاج الطاقة وذات كفاءة عالية الكبح المتجدد- كلاهما غير قابل للتفاوض فيما يتعلق بالسباقات السريعة المتفجرة واستعادة الطاقة في سباقات الفورمولا.

4. الإدارة الحرارية الفعالة: تتفاعل الأسطح الكبيرة والمسطحة لخلايا الكيس بشكل مثالي مع ألواح التبريد السائل. يسحب هذا التصميم الحرارة بسرعة وبشكل متساوٍ، مما يمنع انخفاض الأداء أثناء لفات التصفيات المكثفة أو السباقات الطويلة.

الضرورة الهندسية

يتطلب اختيار الخلايا الجيبية التزامًا هندسيًا متقدمًا. ولا تتحقق فوائدها إلا من خلال:

- تصميم الوحدة المتقدمة: يجب أن يطبق الهيكل الصلب والخفيف الوزن معايير دقيقة ضغط المكدس لإدارة التورم وضمان الاتصال الكهربائي.

- أنظمة حرارية قوية: يعد التبريد المباشر والموحد من خلال الألواح الباردة المتقدمة أمرًا ضروريًا.

- مراقبة الجودة الصارمة: إن الاتساق بين الخلايا من حيث السُمك والسعة والمقاومة أمر حيوي لتحقيق التوازن في العبوة تحت الضغط الشديد.

الخلاصة: التكامل هو كل شيء

في حين توفر خلايا الجيب أعلى إمكانات الأداء، يتم تأمين النصر في مستوى النظام. أفضل خلية هي تلك التي تندمج بشكل مثالي في حزمة مصممة لتوفير طاقة لا هوادة فيها، وتبريد فعال، وسلامة هيكلية.

في شركة لي يو للبطاريات، نتخصص في هذا التكامل. نوفر بطاريات فائقة الطاقة خلايا الأكياس للسيارات الكهربائية وتطوير حلول متكاملة - بما في ذلك الوحدات الهيكلية، وأنظمة التبريد السائل، ونظام إدارة البطاريات القوي - لتشغيل مستقبل السباقات الكهربائية.

هل أنت مستعد لتجاوز حدود الأداء؟ اتصل بنا لدعم مشروعك الفائز القادم.