河南利悦新能源有限公司

カスタムリチウム電池パックの基本ガイド

素晴らしい製品アイデアがあったり、既存のデバイスをアップグレードしたいと思っていても、適切な電源を見つけるのに苦労したことはありませんか?

標準化されたリチウムイオン電池パックは、しばしば妥協を強いられます。サイズが適切でなかったり、電圧、容量、充放電速度が設計に完全に適合しなかったりするかもしれません。こうしたジレンマはあまりにも多く、苛立たしいものです。.

しかし妥協が必要だと誰が言ったのでしょうか?

お客様のニーズにぴったり合うバッテリーを想像してみてください。それがまさに私たちの使命です。カスタムリチウムイオンバッテリーパックを専門とし、バッテリーセルの原材料比率に至るまで、お客様に最適なパワーソリューションをご提案いたします。24年にわたる製造研究開発の経験と、3つの大規模で最新のリチウムバッテリー量産工場を擁しています。.

カスタムリチウムイオンバッテリーパックとは何ですか?

コアコンセプト: カスタマイズされたエネルギーソリューション

こう考えてみてください。標準化されたバッテリーパックは既製服のようなものです。サイズは豊富に揃っていますが、最終的には大衆向けに設計されています。一方、カスタムメイドのリチウムイオンバッテリーパックは、オートクチュールのスーツのようなものです。お客様の製品にぴったり合うよう、細心の注意を払って採寸、裁断、縫製を行います。.

具体的には、これは標準バッテリーでは対応できない特定の要件を満たす、カスタム設計されたエネルギー貯蔵システムです。さらに重要なのは、単に数個のバッテリーセルを接続しただけのシステムではなく、物理的なサイズや重量から出力や動作環境に至るまで、あらゆる変数を考慮した完全統合型システムであるということです。.

主要コンポーネントの理解

カスタムバッテリーパックは高度なエコシステムとして機能します。その構造を明確にするために、4つの主要コンポーネントについて見ていきましょう。.

1. バッテリーセル: パックの心臓

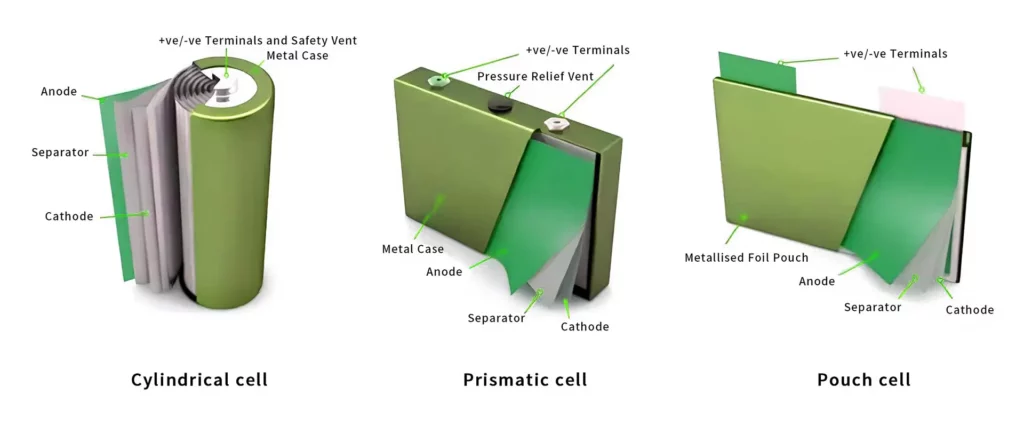

ここでエネルギーが蓄えられます。安全性と長寿命を重視するLiFePO4や、高エネルギー密度を重視するLiPoなど、セルの化学組成と形状(円筒形、角形、パウチ形)の選択が非常に重要です。これらのセルを直列(電圧向上)と並列(容量向上)で接続する方法が、パックのコア性能を決定づけます。.

2. バッテリー管理システム(BMS):インテリジェントな頭脳

BMSはパックのインテリジェントな制御センターとして機能します。この重要な回路は、いくつかの重要な機能を実行します。

- 監視: 電圧、電流、温度を継続的に追跡します。.

- 保護: 過充電、過放電、短絡などの危険な状態からセルを保護します。.

- バランス調整: すべてのセルが均一に充電および放電されることを保証し、全体的な寿命と安全性を最大限に高めます。.

- コミュニケーション: デバイスの充電状態 (SOC) と健全性状態に関する重要なデータを提供します。.

3. パックの構造とハウジング:保護ボディ

このコンポーネントは、すべての部品を統合する物理的な筐体です。堅牢で美しく、内部部品を衝撃、振動、湿気、埃から保護する必要があります。軽量ポリマーから頑丈なアルミニウムまで、材料の選択はアプリケーションの環境要件と設計要件に完全に依存します。.

4. 配線とコネクタ:循環器系

これには、高品質のケーブル、ヒューズ、コネクタが含まれます。適切なゲージの電線と信頼性の高いコネクタを使用することは、安全性と最適なパフォーマンスの両方を確保するために不可欠です。.

カスタマイズの大きな利点

1. 優れたパフォーマンスのための完璧な統合

最大のメリットは、物理的にも電気的にも完璧なフィット感を実現できることです。デバイスのバッテリー収納部は、L字型、曲線型、細長い型など、あらゆる形状に対応できます。このスペースを正確に活用できるようパックを設計しています。その結果、無駄なスペースがなくなり、よりコンパクトで洗練された最終製品を実現できます。.

2. スペースと重量の効率性の向上

パックの形状を最適化し、高エネルギー密度セルを活用することで、一定のサイズと重量で最大限の稼働時間を実現できます。これは、重量が極めて重要なドローンや、人間工学が最優先される携帯型医療機器などの用途において特に重要です。.

3. 長期的な価値とシンプルな拡張性

初期ユニットコストは高くなるかもしれませんが、総所有コストは低くなる場合が多いです。製品寿命の延長、信頼性の向上(保証請求の減少につながります)、そして製品が最適なパフォーマンスを発揮できる電源といったメリットがあります。さらに、適切に設計されたパックは、将来の製品バージョンアップに合わせて容易に拡張できます。.

私たちの共同開発プロセス

カスタム パックの作成は、構造化された共同作業です。.

フェーズ1:包括的な要件分析

これは最も重要な段階です。私たちはお客様と協力して、電気的なニーズ、物理的制約、環境条件、必要な耐用年数、安全認証、予算、スケジュールなど、基本的な質問にお答えします。.

フェーズ2:詳細設計とエンジニアリング

当社のエンジニアリング チームは、セルの選択、BMS アーキテクチャ、機械モデリング、熱管理計画など、お客様の要件を正確な設計仕様に変換します。.

フェーズ3: 厳密なプロトタイピングと検証

その後、機能プロトタイプを限定ロットで製造します。これらのユニットは、電気性能、サイクル寿命、耐環境性などを評価する徹底的なテストを受け、設計の安全性、耐久性、コンプライアンスを検証します。.

フェーズ4:認証と本格生産

試作機の承認後、必要な公的安全認証を取得いたします。認証取得後、量産を開始し、すべてのユニットにおいて一貫した高品質の製品を保証します。.

多様な業界アプリケーション

カスタム電源ソリューションは、さまざまな分野で不可欠です。

- 電気自動車: 当社は、ゴルフ カート、フォークリフト、ユーティリティ ビークル向けに、走行距離と耐久性を拡張する堅牢で大容量のバッテリー システムを提供しています。.

- 医療技術: 当社は、ポータブル診断および生命維持装置向けに、極めて安全で信頼性が高く、軽量なバッテリー パックを設計しています。.

- 産業オートメーション: ロボット工学やバックアップ電源システム向けに、当社は厳しい動作環境向けに設計された頑丈な高出力バッテリーを製造しています。.

- 再生可能エネルギー: 住宅用および商業用の太陽光発電設備では、効率的なエネルギー貯蔵のために安全で長寿命の LiFePO4 化学物質を統合しています。.

- 先進的な民生用電子機器: 当社のフレキシブル パウチ セルは、ドローン、プロ用オーディオ/ビデオ機器、スマート ホーム デバイス向けに、革新的でスペース効率の高い設計を実現します。.

信頼できるバッテリー開発パートナー

メーカーの選定は重要な決断です。実績のある専門知識、強力なエンジニアリング能力、妥協のない安全性への取り組み、そして透明性のあるコミュニケーションを備えたパートナーが必要です。24年にわたる業界経験、完全なプロセス管理、そして品質重視のアプローチを備えた当社は、まさにそのようなパートナーとなるための体制を整えています。.