Henan Liyue Nova Energia Co., Ltd

From Inquiry to Integrated Power Solution: Engineering a Custom Industrial Battery System

At our LiFePO4 battery factory, a recent inquiry from an electrical design engineer perfectly encapsulates the evolving needs of modern industry. The request was for a robust, plug-and-play battery system comprising a custom battery pack, a docking station with AC/DC output, and a separate charging dock—all built for demanding industrial environments.

This project is a prime example of moving beyond simple cell supply to providing a complete, engineered power solution. For OEMs and product designers, here is a breakdown of how we approach such integrated projects from concept to reality.

Core Need: Industrial-Grade Reliability and Flexibility

The client’s requirements highlight critical priorities for industrial equipment:

- Operational Continuity: A hot-swappable battery dock ensures zero downtime; one pack powers the device while another charges.

- Environmental Robustness: Mechanical and electrical design must withstand dust, vibration, and frequent handling.

- User-Centric Design: A true plug-and-play experience demands intuitive, safe insertion/removal and clear status indication.

- Output Versatility: Providing standard AC (110V) or DC (24V) output directly from the dock simplifies integration with end-user equipment.

Our End-to-End Development Process

For such OEM/ODM customized solutions, we engage in a collaborative, phased process:

Phase 1: Discovery & Specification

We begin by detailing all technical parameters. For this project, we would request:

- Detailed Power Profile: Peak/sustained power (W), energy capacity (Wh), and desired runtime per pack.

- Mechanical Constraints: Maximum dimensions for the battery pack and dock to fit the host equipment.

- Interface & Connectivity: Preferred connector types (e.g., Anderson, XT), communication protocols (e.g., CAN, UART), and status LED requirements.

- Environmental & Certification Standards: Required ingress protection (IP rating), shock/vibration specs, and target certifications (UL, CE, UN38.3).

Phase 2: Integrated Design & Engineering

This is where our expertise across multiple disciplines converges:

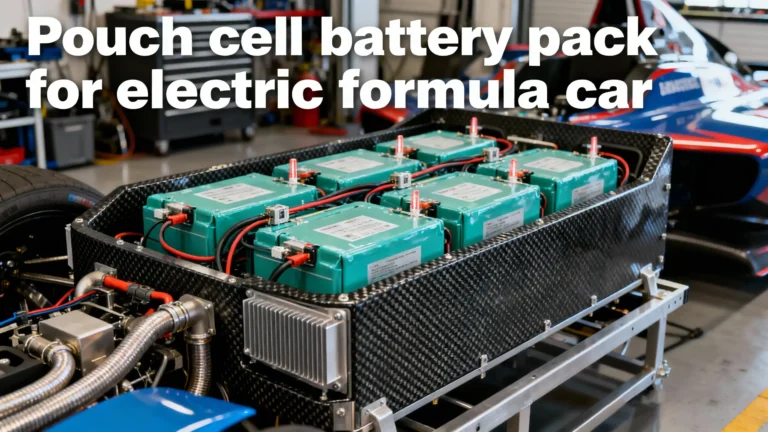

- Custom Battery Pack Design: Utilizing our high-safety LiFePO4 pouch cells, we design the optimal series-parallel configuration within the custom housing. The focus is on energy density, thermal management, and structural integrity.

- Advanced BMS & Safety Protections: We engineer a tailored Battery Management System with protections for overcharge, deep discharge, high current, short circuit, and temperature. The BMS ensures communication between the pack, dock, and charger.

- Mechanical Housing & Docking System: Our team designs the battery stand/dock e charging dock for durability and safety. This includes robust mechanical locks, proper electrical contact alignment, and thermal design for safe charging in ambient conditions.

Phase 3: Prototyping, Validation & Delivery

- A functional prototype is built for client testing and feedback.

- The system undergoes rigorous validation against the agreed specifications.

- Upon approval, we move into pilot production and full-scale manufacturing with consistent quality control.

Why Partner with Us for Your System Integration?

This project underscores the advantage of partnering with a manufacturer that controls the core cell technology and possesses full-stack integration capabilities.

- Single-Point Accountability: From cell to system, we manage the entire supply chain and quality process.

- Safety by Design: Our foundation in inherently safe LiFePO4 chemistry is bolstered by system-level safety engineering in the BMS and mechanical design.

- Engineering Partnership: We function as an extension of your team, translating complex requirements into a reliable, manufacturable product.

Ready to transform your custom power concept into a market-ready system?

Whether you need a sophisticated docking solution or a fully custom battery pack, our engineering team is ready to collaborate. Contact us today to initiate a technical discussion and share your preliminary specifications.