Henan Liyue Yeni Enerji Co, Ltd

Warehouse Battery Upgrade: LiFePO4 Case Study Boosts Efficiency 40%

Introduction: Unlocking Efficiency with a LiFePO4 Battery Upgrade

What if the key to boosting your warehouse efficiency was already in your facility, powering your equipment? From my 25 years in the battery industry, the single most impactful change for logistics centers is often a strategic battery upgrade. This case study details how a regional distribution center replaced their lead-acid batteries with Lithium Iron Phosphate (LiFePO4) solutions, transforming their operational capacity and bottom line.

The Core Challenge: Systemic Downtime

Our client, a mid-sized e-fulfillment warehouse, faced industry-standard pains with their 50+ electric material handling vehicles. The lead-acid battery lifecycle mandated lengthy charges and spare pools, creating 1.5 hours of daily downtime per vehicle. Hidden costs from maintenance, replacements, and dedicated charging rooms were substantial, while performance faded noticeably each shift, hindering throughput and safety. According to a report by the Industrial Truck Association, unplanned downtime is a top cost driver in material handling.

Our Engineered Solution: A LiFePO4 Power Battery Overhaul

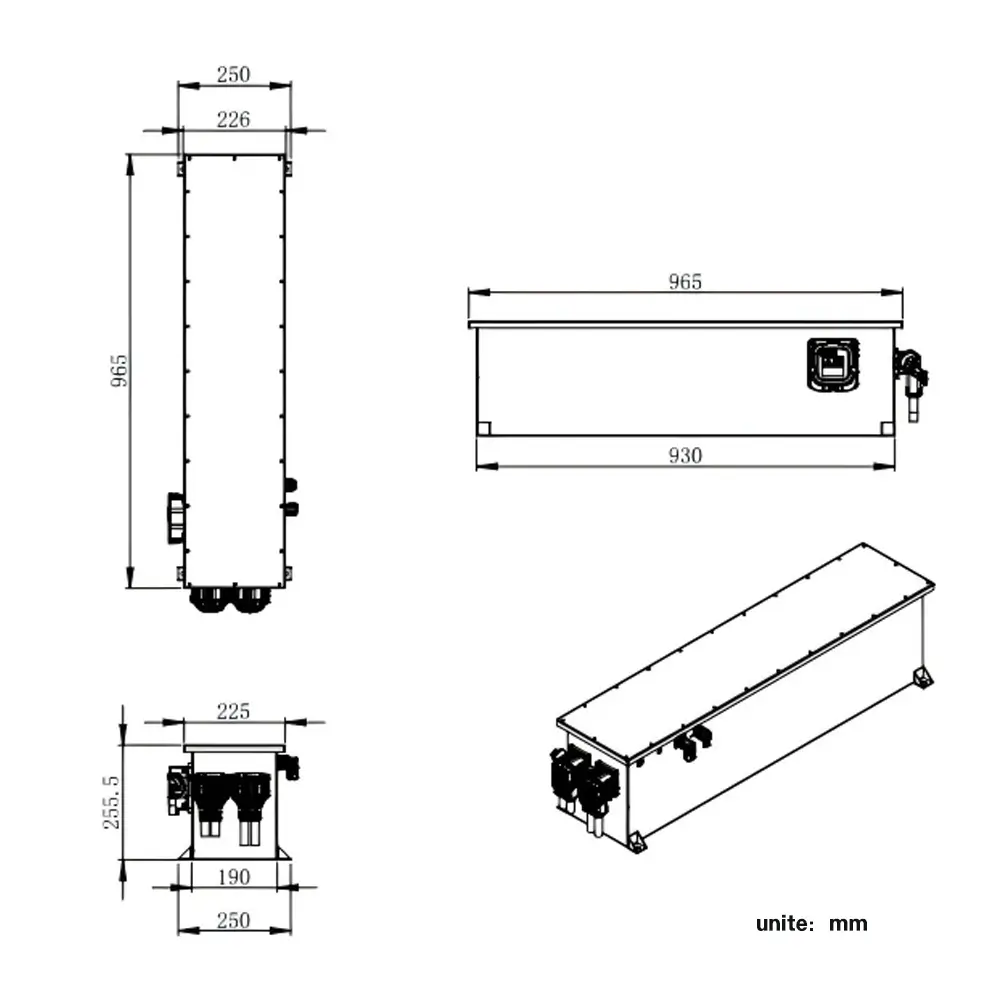

We implemented a phased warehouse efficiency upgrade centered on high-performance LiFePO4 battery systems. The solution included direct-fit 48V 400Ah packs for pallet trucks and 48V 500Ah systems for forklifts, paired with smart opportunity chargers and cloud-based telematics for real-time monitoring. This approach was designed not just to replace, but to redefine their power management, a principle supported by research from ENERGY STAR on warehouse energy efficiency.

Measurable Results from the Battery Upgrade

Post-implementation data confirmed a dramatic shift. The LiFePO4 battery upgrade delivered:

- ~40% Increase in average productive runtime per vehicle.

- 100% Elimination of mid-shift battery swap downtime.

- ~70% Reduction in annual energy and maintenance costs per vehicle.

- A 5x+ extension in expected battery life.

| KPI Metric | Before (Lead-Acid) | After (LiFePO4) | Gelişim |

|---|---|---|---|

| Productive Runtime/Day | 13 hours | 18+ hours | ~40% Increase |

| Mid-Shift Downtime | 1.5 hours | 0 hours | 100% Eliminated |

Client Verification and Long-Term Gains

“Fleet availability transformed overnight,” the client’s Operations Director noted. “The efficiency gains during peak season were critical, and the project achieved a payback period under 18 months.” Beyond the numbers, the upgrade simplified management, improved operator morale with consistent power, and enhanced facility safety by removing hazardous materials.

Replacing lead-acid batteries with lithium batteries is an inevitable trend

This case study demonstrates that a modern battery upgrade is a direct investment in productivity and resilience. For operations burdened by the limitations of lead-acid technology, the path to significant efficiency improvement is clear.

Explore our full range of proven industrial power solutions or contact me directly for a complimentary efficiency assessment.

Related Reading: Technical Guide: 48V 50Ah vs. 400Ah LiFePO4 Packs for Gantry Cranes

Power your productivity. Contact our engineering team today.