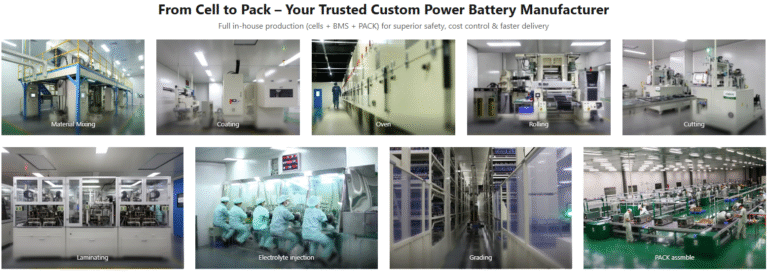

Henan Liyue New Energy Co., Ltd

Industrial Power Solutions: A Strategic Guide for Modern Operations

Introduction: Rethinking Power as a Strategic Asset

After twenty years of designing industrial power solutions, I’ve witnessed a fundamental shift. Power is no longer just a utility—it’s a core strategic lever for productivity, reliability, and profitability. Whether you’re running a fleet of forklifts, automated guided vehicles (AGVs), or heavy-duty cranes, the right power system directly impacts your bottom line. This guide explains why modernizing your power infrastructure is the most impactful efficiency upgrade you can make.

The High Cost of Outdated Power Systems

Many facilities operate on legacy systems, primarily lead-acid batteries, without fully accounting for their total cost. The challenges are universal:

- Operational Downtime: Scheduled charging and battery swaps can idle critical equipment for hours each day. This is a direct drain on throughput, a point emphasized in studies on material handling efficiency.

- Hidden Ownership Expenses: Beyond purchase price, costs balloon from energy-inefficient charging, dedicated ventilation and space, constant maintenance, and frequent replacements every 12-18 months.

- Performance Inconsistency: Voltage drop during discharge leads to slower operation and reduced capability, affecting both safety and cycle times.

- Management Complexity: Tracking, watering, and maintaining a large bank of individual batteries is a significant logistical burden.

The Modern Industrial Power Solution: Lithium Iron Phosphate (LiFePO4)

Today’s answer to these challenges is a system-wide upgrade to Lithium Iron Phosphate technology. A modern industrial power solution built on LiFePO4 isn’t just a “battery swap”; it’s an integrated ecosystem comprising:

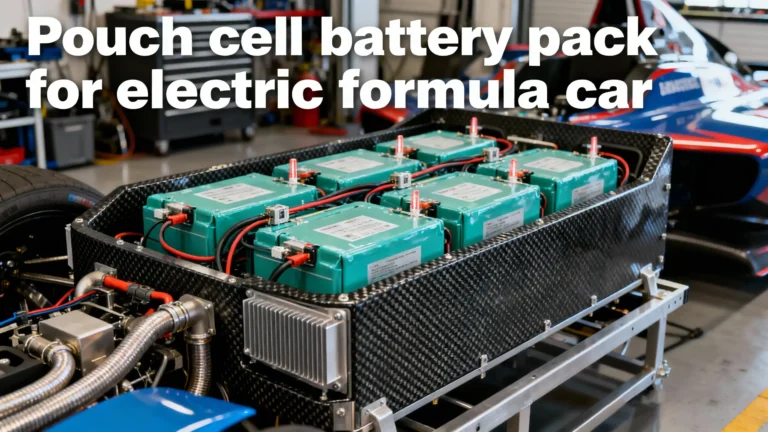

- High-Density Battery Packs: Engineered for specific applications—from 48V packs for pallet jacks to high-voltage systems for AGVs and heavy machinery.

- Smart Charging Infrastructure: Fast, opportunity chargers that enable top-ups during breaks without damaging battery life.

- Cloud-Based Energy Management: Telematics that provide real-time data on state-of-charge, health, and location, enabling predictive maintenance and optimal fleet deployment.

- Seamless Integration: Solutions designed for drop-in compatibility or custom-engineered for new equipment.

Key Applications Transforming Industries

This technological shift is driving efficiency across sectors:

- Warehousing & Logistics: Enabling 24/7 shift operations with no battery-change downtime.

- Manufacturing: Providing stable, clean power for automated production lines and AGVs, eliminating voltage-spike disruptions.

- Construction & Heavy Machinery: Delivering high-power, reliable energy for electric cranes, lifts, and tools in emission-sensitive sites.

- Ports & Rail Yards: Powering electric cargo handlers with the endurance and rapid recharge needed for continuous operation.

Quantifying the Return on Investment (ROI)

The business case for upgrading your industrial power system is clear and measurable. Facilities typically report:

- >40% Increase in equipment availability and utilization.

- 60-70% Reduction in total energy and maintenance costs per unit.

- Elimination of battery-change downtime and associated labor.

- 3-5x Longer operational life compared to lead-acid, as supported by lifecycle analyses from institutions like Fraunhofer Institute for Systems and Innovation Research.

Implementing Your Power Strategy: A Phased Approach

A successful transition requires careful planning:

- Audit & Analysis: Assess current energy usage, duty cycles, and pain points.

- Pilot Program: Deploy solutions in a controlled area to validate performance and ROI.

- Phased Rollout & Training: Scale the solution while training operators and maintenance teams on new protocols.

- Integration & Optimization: Connect power management data to your facility’s control systems for holistic oversight.

Conclusion: Powering the Future of Industry

The evolution from passive power components to intelligent, integrated industrial power solutions represents a defining competitive advantage. It’s an investment that pays dividends in reliability, cost savings, and operational agility.

Is your facility running on the power technology of the past?

Explore our comprehensive suite of engineered power systems or connect with our consultants for a free, data-driven Power Infrastructure Assessment.

Deepen Your Knowledge:

Case Study: How a LiFePO4 Upgrade Boosted Warehouse Efficiency by 40%

Technical Brief: Selecting 48V Battery Packs for Gantry Crane Applications

Ready to transform your operational power? Contact our engineering team today.