Henan Liyue New Energy Co., Ltd

The Essential Guide to Battery Pack Engineering for Energy Storage Systems

Introduction: The Engineered Heart of Energy Storage

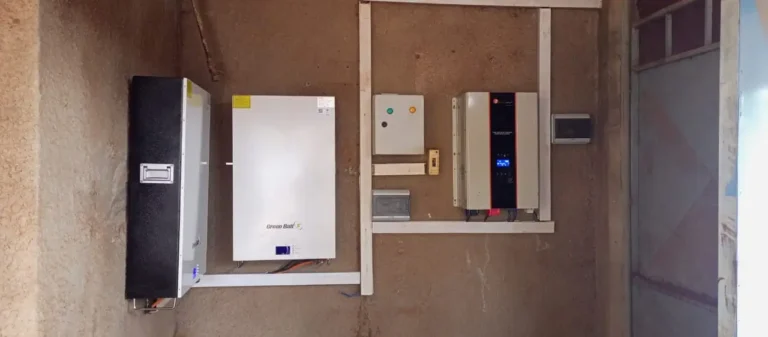

A modern lithium-ion battery pack is a masterpiece of systems engineering. Far more than a mere container for cells, it is an integrated electromechanical system designed for safety, longevity, and performance. As the core of any Energy Storage System (ESS), its design dictates efficiency, scalability, and total cost of ownership. This guide, from the perspective of battery pack engineering, explores the fundamental components, critical manufacturing processes, and key technology pathways that define today’s solutions.

Core Components: Anatomy of a Battery Pack

A reliable lithium battery pack is a synergy of several critical subsystems working in concert.

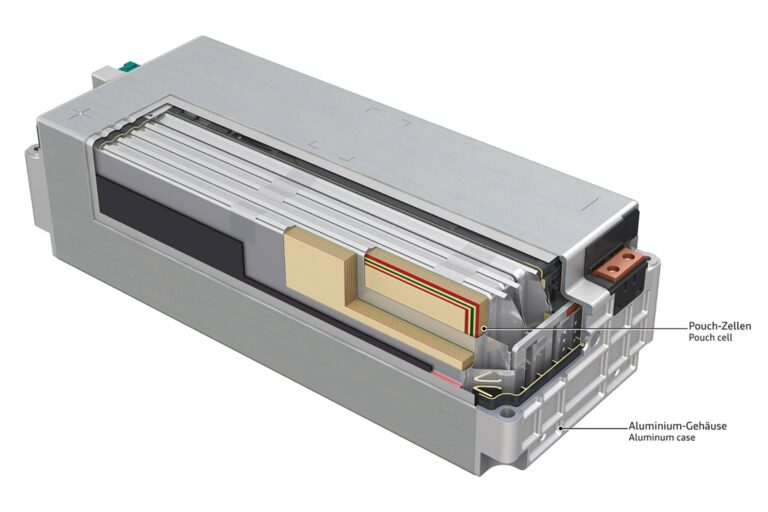

Battery Modules: The Fundamental Building Blocks

Modules are created by connecting individual cells in series and/or parallel to achieve target voltage and capacity. Common configurations use 8 to 14 cells per module. For example, a 1P48S pack may comprise four 12S modules, forming the foundational voltage block for the system.

The Electrical Connection & Safety System

This network ensures efficient and safe current flow. It includes:

- Busbars (CCS): For low-resistance interconnections.

- Wiring Harnesses: Segregated high-voltage and low-voltage lines.

- Protection Devices: Fuses, contactors, and breakers that isolate faults.

Thermal Management System: Ensuring Longevity

Critical for safety and cycle life, it maintains an optimal operating temperature (typically 20°C-30°C). Liquid cooling (via cold plates) is becoming standard for high-power density packs due to its superior heat transfer efficiency compared to air cooling.

Structural Enclosure & Mechanical Design

The pack enclosure provides mechanical integrity, environmental protection (IP rating), and safety containment. It must withstand vibration, impact, and sometimes thermal runaway events, while enabling efficient serviceability.

The Battery Management System (BMS): The Pack’s Intelligence

The BMS is the indispensable “brain” of the operation. Its functions are multi-layered:

- Monitoring: Precision measurement of cell voltage, temperature, and current.

- Protection: Safeguarding against over/under-voltage, over-current, and extreme temperatures.

- Balancing: Actively or passively equalizing cell states to maximize capacity.

- Communication: Providing state-of-charge (SOC), state-of-health (SOH), and diagnostic data to the external Energy Management System (EMS).

Critical Manufacturing & Assembly Processes

The reliability of a pack is determined on the production floor through precise processes.

Cell Sorting & Precision Matching

High-throughput testing equipment groups cells by voltage, capacity, and internal resistance. Matching within a tight tolerance (e.g., <2%) is paramount to ensure pack balance, performance, and longevity from the very first cycle.

Advanced Joining & Welding Technologies

Electrical connection integrity is non-negotiable. Laser welding offers speed and consistency for permanent busbar connections, while ultrasonic welding is key for foil tab connections in pouch cells. The choice directly impacts electrical resistance and long-term reliability.

Key Technology Pathways & Design Decisions

Engineers navigate several fundamental choices when architecting a pack solution.

System Architecture: Low-Voltage vs. High-Voltage

- Low-Voltage (e.g., 48V): Utilizes a simpler 1P16S topology. Benefits include mature, cost-effective BMS technology and the ability to use very large format cells (e.g., 280Ah+). It dominates price-sensitive and residential markets, though higher currents lead to greater resistive losses.

- High-Voltage (>400V): Constructed by stacking multiple modules in series. The higher voltage means lower current for the same power, reducing cable size and copper losses, thereby increasing overall system efficiency. This architecture is standard for commercial, industrial, and utility-scale ESS.

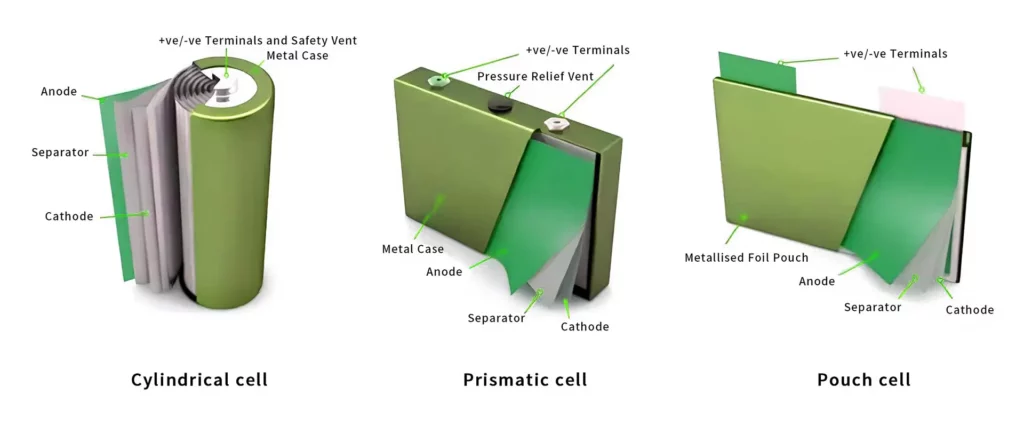

Cell Form Factor Selection: A Trade-Off Analysis

- Prismatic cell (Aluminum Shell): The dominant choice for stationary storage. Offers excellent packaging efficiency, mechanical stability, and simplifies liquid cooling integration. Its standardized format enables automated, high-volume production.

- Cylindrical cell (e.g., 21700, 4680): Provides proven manufacturing scale and inherent safety from a robust steel casing. Module assembly can be more complex, but its design allows for efficient thermal runaway propagation control.

- Pouch cell: Delivers superior energy density and lightweight design. Its main challenges for large-scale ESS include greater need for mechanical support in the module and more complex swelling management over life.

Cell Capacity & Chemistry: Aligning with Application

Capacity selection is driven by use-case economics and physics.

- Residential ESS: Heavily utilizes 50Ah to 100Ah prismatic LFP (Lithium Iron Phosphate) cells, prized for safety and cycle life. The 280Ah+ cell is a game-changer, enabling high-energy, low-voltage packs.

- Grid-Scale ESS: Embraces the 280Ah to 314Ah+ LFP prismatic cell. Its high capacity reduces the part count per MWh, simplifying assembly and BMS management in massive 1P52S or 1P104S configurations for 1000V/1500V systems.

Henan Liyue New Energy Co., Ltd. delivers engineered lithium battery pack solutions, integrating advanced cell technology, robust BMS software, and rigorous pack validation for global energy storage applications.

Have a specific project requirement or a technical challenge? Contact our engineering team for a data-driven design consultation.