Henan Liyue New Energy Co., Ltd

Integrated Battery Manufacturing: Our Specialized Approach

Integrated battery manufacturing provides distinct advantages in cost efficiency and quality control for specialized applications

The global lithium battery market features several established leaders. CATL maintains its position as the world’s largest manufacturer, while BYD follows with strong vertical integration capabilities. Other significant players include LG Energy Solution, Panasonic, and SK Innovation, each bringing distinct technological strengths to various market segments.

These major manufacturers have established substantial production capacity and continue to invest heavily in research and development. However, their scale can sometimes limit flexibility for specialized applications, creating opportunities for focused manufacturers to excel in specific market segments.

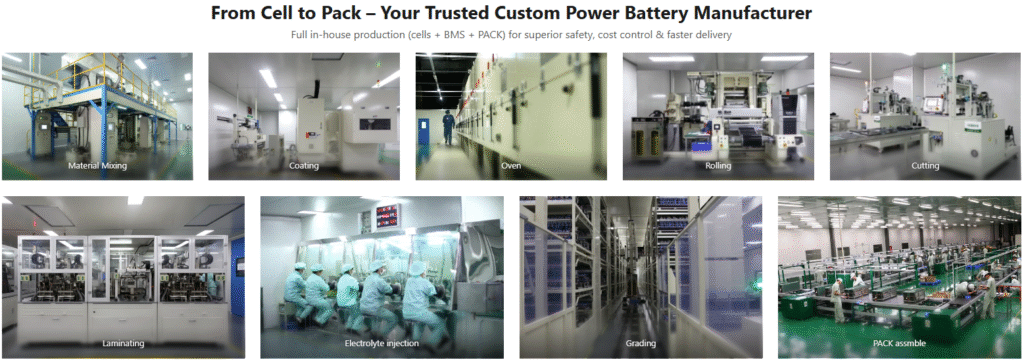

Our Manufacturing Approach

We operate a fully integrated battery manufacturing facility that handles both pouch cell production and complete pack assembly within the same location. Our specialized approach offers particular benefits for applications requiring:

- Electric forklifts and material handling equipment

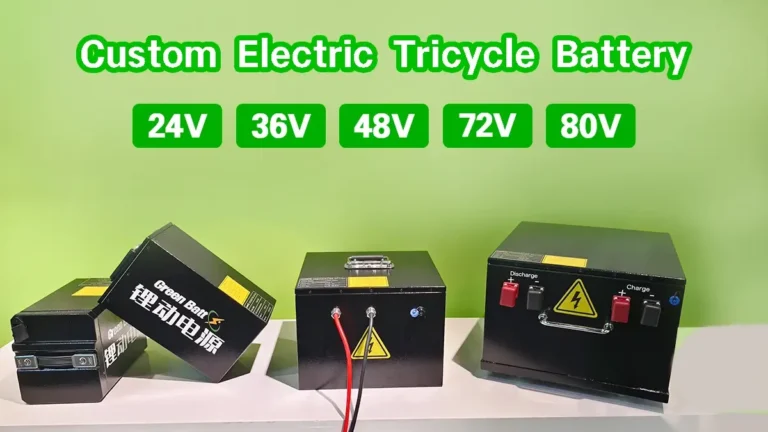

- Utility vehicles and specialized mobility solutions

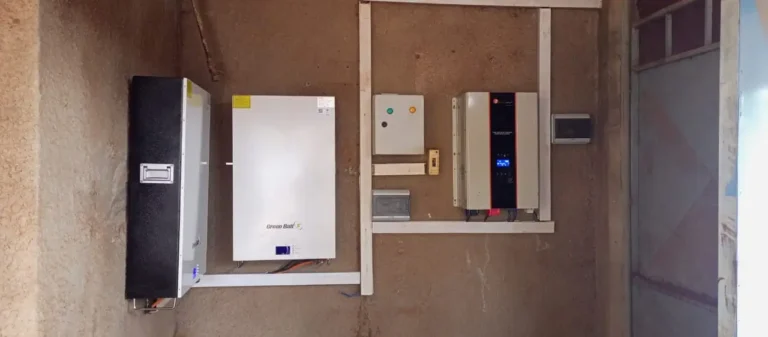

- Residential and commercial solar energy storage systems

- Portable power applications

Technical Capabilities

Our pouch cell production focuses on 3.2V pouch cells with capacities ranging from 20Ah to 80Ah, providing:

- Balanced energy density and cycle life

- Enhanced safety characteristics

- Design flexibility for various configurations

- Reliable performance across operating conditions

With 5GWh annual production capacity and ongoing automation investments, we maintain both scale capability and specialized focus.

Our Factory Advantages

Cost Efficiency

Integrated manufacturing eliminates multiple transportation and handling steps, reducing production costs by 20-30% compared to segmented approaches. These efficiencies directly benefit customers through competitive pricing.

Quality Consistency

Complete control over the entire production process ensures consistent quality standards from cell manufacturing through final pack assembly. This eliminates compatibility issues that can arise when components come from different facilities.

Production Flexibility

Our integrated facility enables responsive adjustment to customer requirements, with ability to implement design changes and accommodate special requests within 24 hours.

Customer Results

Documented outcomes include:

- 28% reduction in total battery costs for material handling applications

- 60% decrease in warranty claims due to improved compatibility

- 40% faster project completion for energy storage installations

- Simplified procurement through single-source responsibility

Our integrated battery manufacturing approach provides practical advantages for applications requiring cost efficiency, quality consistency, and responsive service.

We welcome discussions about specific application requirements and facility visits to observe our manufacturing processes directly.

Contact us to explore how our battery solutions can meet your needs for specialized applications.